- Products

- Impact & abrasion protection

- Bend & fatigue protection

- Buoyancy & floats

- Downhole protection

- Guides & clamps

- Seabed stability

- Sensors & monitoring

- Sectors

- About us

- Knowledge

- News

- Careers

- Contact

Increasing application demands require an increased understanding of the mechanical, physical, hydrostatic and chemical properties of our materials. Polymeric materials are notably sensitive towards any changes in their chemistry or their processing methodology. It is critical that we can understand in detail not only the natural variation in observed properties, but also how even slight changes to how materials are formulated or manufactured, can affect their final properties.

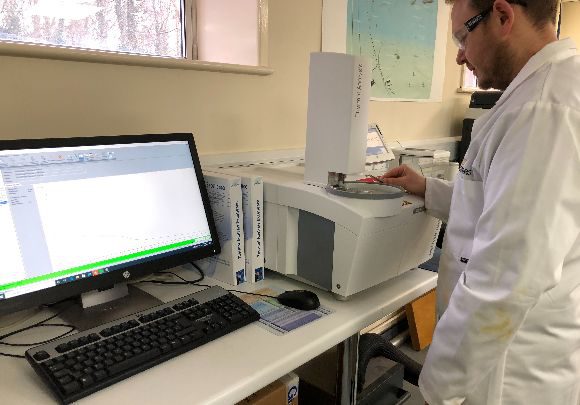

CRP Subsea has the capability to carry out a wide variety of testing on a laboratory scale. Testing covers everything from material characterisation to final mechanical and hydrostatic testing. With highly skilled technicians using state-of-the-art equipment, we understand more about each material with every test performed. This understanding and increased knowledge enables us to ensure the products we engineer for our customers are suited to their specific requirements and that their performance is unrivalled. From fourier-transform infrared spectroscopy to long-term hydrostatic testing, the range of testing available from CRP Subsea, ensures that product performance can be assessed and predicted accurately. We have the capability to validate predictions based on lab results on a much larger scale, due to our well-equipped testing facilities.

Alongside our extensive in-house test capability, we are partnered with several external test houses to enable us to offer a full suite of testing. A large proportion of testing carried out is performed throughout production cycles as part of quality control procedures. Testing is also conducted as part of material qualification programs, new product development, root cause analysis & material characterisation. From incoming goods testing to mechanical testing post manufacture, we perform highly specialised and design critical tests, to ensure that all products manufactured are of the highest quality both chemically and physically

Physical testing is performed to validate the fundamental performance of a material following manufacture and provide accurate and precise mechanical properties of all materials for design purposes. Physical testing such as tensile strength and abrasion resistance are carried out to ASTM and ISO specifications to ensure accurate test methodology. Many physical tests performed are as a result of internal quality control procedures or specific customer requirements, however, physical testing is also a key aspect of CRP Subsea’s material qualification programs, root cause analysis as well as more general research and development. Having a wide array of physical testing apparatus available ensures that both external and internal projects, proceed without extended delays whilst mechanical properties are tested, or designs validated externally.

Our highly skilled technicians are trained not only in test operation, but also in the chemistry of the materials they are testing. This ensures that tests are not performed to simply “tick a box” but are performed in a manner that allows for all aspects of the test to be examined and detailed. Failure modes and break interfaces can often tell us more about the material than the mechanical result itself. Our test technicians recognise and understand it is critical to extract as much information as possible from each individual test.

Due to extremely high pressures observed by composite materials during use in deep-water environments, it is vital to test the hydrostatic strength and assess suitability in service. CRP Subsea has a large suite of pressure vessels varying in size, pressure and temperature capability, thus ensuring that every batch of material manufactured is fit for purpose. We detail stringent quality control criteria to ensure the quality of each individual product’s hydrostatic performance, using over 30 years of data and experience.

It is a well-known fact that polymers degrade as they age, this aging process and its effect on the mechanical performance of the polymer varies as a result of multiple factors. Common aging mediums materials are subjected to include freshwater, saltwater, salt-spray and air, maintained at a range of temperatures and pressures. The specific combination of temperature, pressure and the aging medium can degrade the material to different extents, understanding this ensures that products are able to perform to their highest standards for the entire duration of their designed life.

Understanding and controlling the chemistry of the materials used to make highly engineered polymers is always the first step in the design and manufacture of high-quality polymeric systems. Analysis of raw materials on a molecular level, not only ensures that the materials used in formulations are of high quality and consistent structure, but also allows formulations to be tailored in a way that takes full advantage of a polymer’s capability. From simple pH measurements and furnace burn-off testing to analysis using rheometers and auto-titrators, chemists and materials engineers at CRP Subsea use a wide array of equipment to validate the notion that everything starts with precise & well-balanced chemistry.

The thermal properties of a polymer are critical in the performance of an engineered system, different polymers can show a wide variety of performance characteristics across a range of temperatures. Understanding this is just as important as knowing its final mechanical properties such as its ultimate tensile strength. For a given temperature gradient, a polymer can go through multiple phase transitions which alters the way in which it behaves, examples of these transitions include the glass transition temperature (HTT), heat distortion temperature (HDT) and coefficient of thermal expansion (CTE). These properties are used in the design of polymeric systems at CRP Subsea to provide optimum performance in all different types of service conditions.