- Products

- Impact & abrasion protection

- Bend & fatigue protection

- Buoyancy & floats

- Downhole protection

- Guides & clamps

- Seabed stability

- Sensors & monitoring

- Sectors

- About us

- Knowledge

- News

- Careers

- Contact

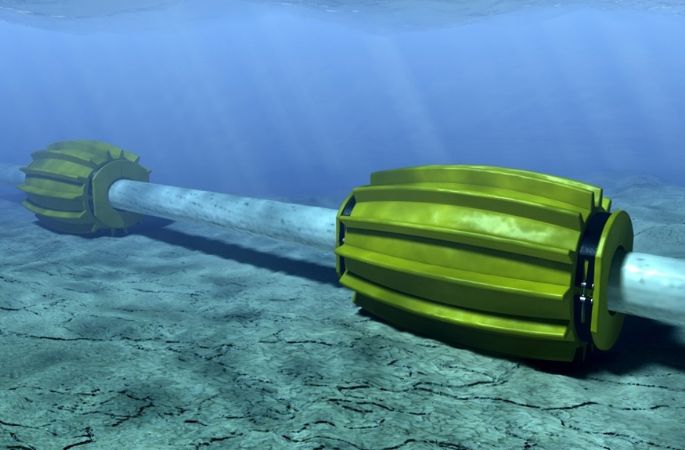

Rotating Buoyancy Modules are used to mitigate buckling in seabed pipelines. Buckling occurs during start-up and shutdown sequences as the thermal fluctuations cause pipelines to expand and contract, leading to problematic buckling along its length.

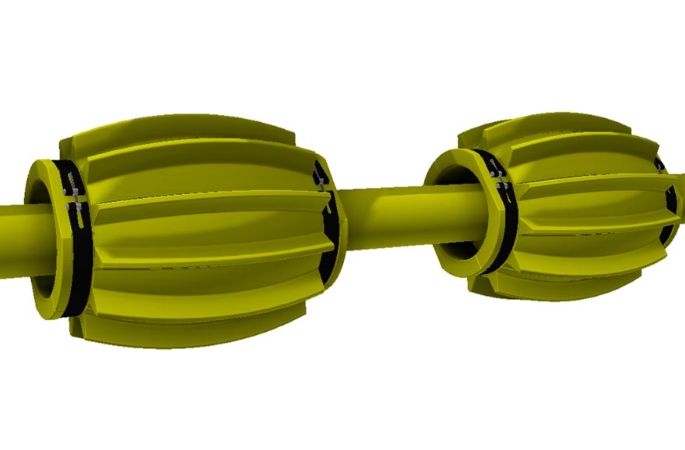

Traditionally non-rotating cylindrical buoyancy modules have been installed along sections of the pipeline, to reduce the weight and friction in that section and promote controlled bending. However, in certain conditions, the modules have displaced seabed material to build berms (ridges) that have then restricted the lateral movement the modules were installed to promote.

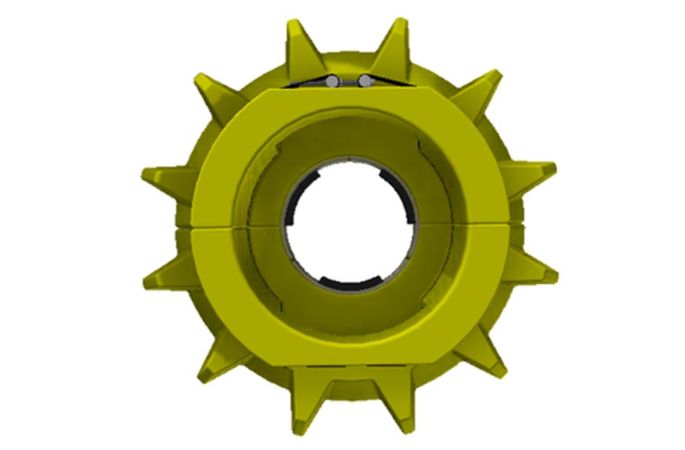

Rotating Buoyancy Modules roll on the seabed reducing lateral friction and berm creation, allowing repeatable and predictable pipeline behaviour by eliminating rogue buckles in the pipeline. As a consequence, it allows for project cost reduction, as a lower quantity of buoyancy modules are used to create ‘safe buckling zones’.

Predictable safe buckling zones

Reduce berm creation

Eliminate rogue buckles

Quick installation

Reduced project costs

Seabed pipeline

Seabed flowlines