- Products

- Impact & abrasion protection

- Bend & fatigue protection

- Buoyancy & floats

- Downhole protection

- Guides & clamps

- Seabed stability

- Sensors & monitoring

- Sectors

- About us

- Knowledge

- News

- Careers

- Contact

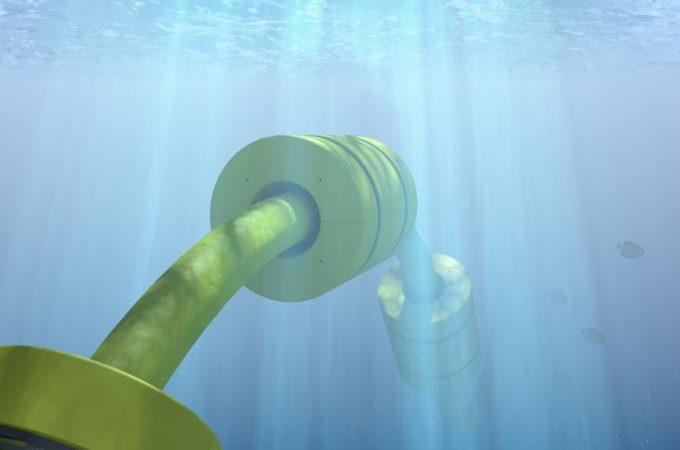

In floating production scenarios, pipelines such as flexible risers, cables, and umbilicals are often required to be held in specific geometric configurations subsea, designed to prevent damage of the system. Although numerous configurations have been developed and implemented over the years, one favoured method is to attach discrete Distributed Buoyancy Modules to the outside of the pipeline. The buoyant load must not migrate or degrade over the design life of the product.

Distributed Buoyancy Modules are typically used between a subsea structure and a surface vessel or platform. The clamping solution allows the Distributed Buoyancy Modules to be fitted at any point along the length of the pipeline.

The two main functions of the Distributed Buoyancy Modules are to provide uplift and maintain location along the riser. The uplift is generated by a two-part buoyancy component. A clamp securely attaches the assembly to the desired location on the riser. The buoyancy segments are assembled to mechanically lock around the clamp and are secured with circumferential straps.

To provide the required project performance, the buoyancy system can be adjusted to operate in seawater depths from surface to 6,000 metres and beyond.

Reduces top tension loads

Maintain project specific riser configuration

Fast, efficient and safe offshore installation

Provide uplift

Maintain location along the flexible pipeline or cable

Compliant clamping systems

Deep water buoyancy systems

Insulated risers

Dynamic applications

Wind farm cables