- Products

- Impact & abrasion protection

- Bend & fatigue protection

- Buoyancy & floats

- Downhole protection

- Guides & clamps

- Seabed stability

- Sensors & monitoring

- Sectors

- About us

- Knowledge

- News

- Careers

- Contact

Buckling arises when Flowlines deviate from their intended design configuration on the seabed. Buckling often occurs during start-up and shutdown sequences as the thermal fluctuations cause pipelines to expand and contract, leading to problematic buckling along its length.

The movements can cause high compression forces, bending moments, and shear forces that affect the flowline integrity. To relieve these stresses, the pipeline's natural response would be to buckle. Adding buoyancy to the Flowline in discrete locations can help control the movement and mitigate buckling.

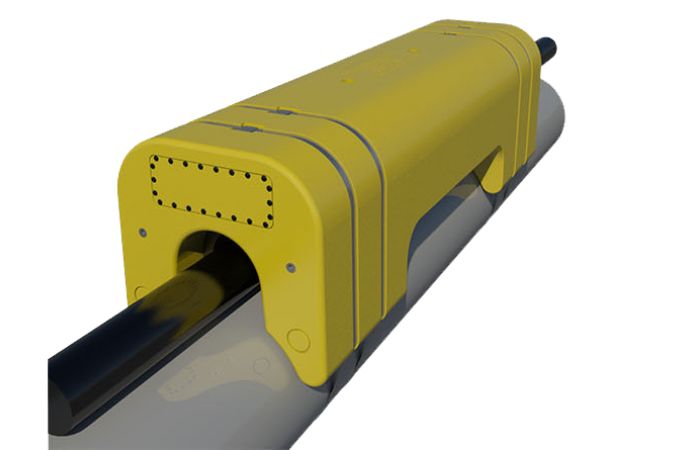

Placement of the Flowline Buckling Mitigation eliminates risk by promoting controlled flowline movement and mitigates flowline buckling. Each Flowline Buckling Mitigation Buoyancy Module has an engineered structural core ensuring maintenance-free performance throughout the design life.

The Flowline Buckling Mitigation Buoyancy Module skin provides a tough exterior that protects the buoyancy core during handling, deployment, and operation. The nature of the design allows the net buoyancy to be adjusted to suit each individual application with systems qualified up to 3,000 metres.

Predicable flowline configuration behaviour

Quick installation

Reduced project costs

Qualified to 3,000 metres

Tailored solutions

Suitable for use on seabed

High temperature high pressure pipelines

Seabed flowlines