- Products

- Impact & abrasion protection

- Bend & fatigue protection

- Buoyancy & floats

- Downhole protection

- Guides & clamps

- Seabed stability

- Sensors & monitoring

- Sectors

- About us

- Knowledge

- News

- Careers

- Contact

When a flexible pipeline, umbilical or cable connects to a rigid structure, normal movement during operation or forces incurred during installation and retrieval, can cause damage and failure at the connection point. A bend restrictor controls the bending of the flexible pipeline, umbilical or cable to prevent damage from occurring.

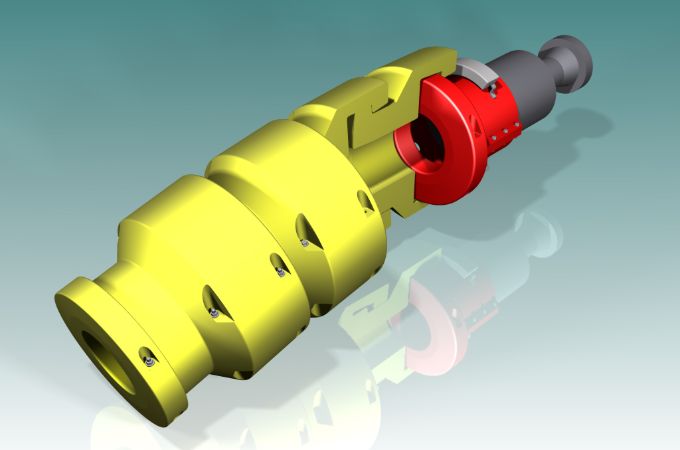

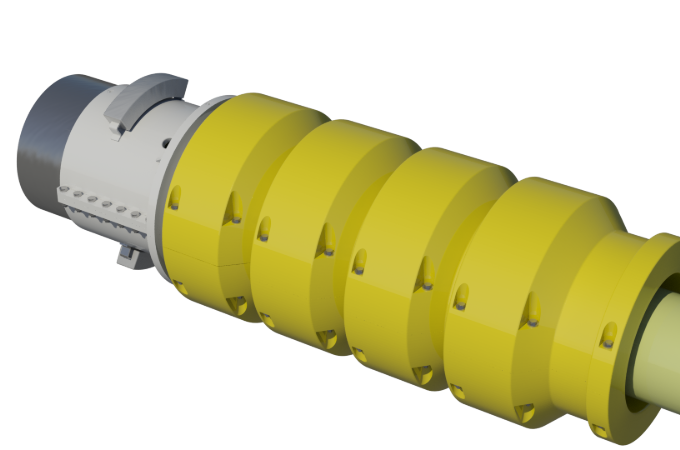

The Bend Restrictor has been designed to protect flexible pipelines, umbilicals and cables from over bending and buckling during their installation or operation. The system comprises of a number of interlocking elements that form a semi-rigid curved structure, engineered to inhibit bending beyond a designated minimum bending radius (MBR) at a specified design load in static and quasi-static applications, on any diameter subsea cable, umbilical, riser or flowline.

The Bend Restrictor two-piece, polymeric, split design is attached to the pipeline or cable during deployment, improving installation efficiencies without compromising on joint integrity or cascade failure risks between parts. Typically deployed at pipeline end terminations (PLETs) and wellhead connectors, Bend Restrictors can be supplied with specific end terminations to allow for easy mating to any rigid structure that needs to protect its flexible pipeline, umbilical or cable from overbending, for example tether clamps.

Bend Restrictors are available as both a standardised product for a wide range of common diameters, loads and MBRs, reducing lead time and increasing installation efficiencies, and alternatively as a fully bespoke solution allowing design customisation of a wide range of features, providing a custom approach for your specific application.

Protection from over bending and buckling

Provides a suitable load path from flexible to fixed structures

Standardised and bespoke custom design options available

API 17L certified material

Reduced mass per metre

Marine grade polymers and corrosion resistance

Subsea flexible pipelines, umbilicals and cables

SURF protection at end terminations

Flexible risers and jumpers

Steel tube and thermoplastic umbilicals

Thermoplastic composite risers

Flowlines

Fiber optic cables and communications