- Products

- Impact & abrasion protection

- Bend & fatigue protection

- Buoyancy & floats

- Downhole protection

- Guides & clamps

- Seabed stability

- Sensors & monitoring

- Sectors

- About us

- Knowledge

- News

- Careers

- Contact

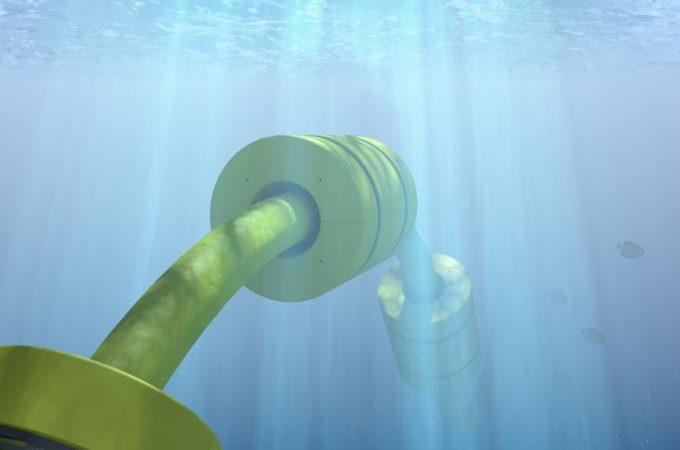

Whatever application you are interested in (steel or flexible risers, cables or umbilicals) CRP Subsea has a buoyancy clamping solution to meet your needs. With over 47,000 buoyancy modules supplied and in service for up to 30 years, we have the experience and expertise to design the right buoyancy clamping solution for all your requirements.

The primary function of a clamp is to maintain the location of each buoyancy module assembly along the pipeline to which it is attached. The clamp must resist any axial movement due to the loads placed on it from both buoyancy of the module (during installation and operation) as well as the weight in air of the buoyancy module (during installation), over the required life time of the Distributed Buoyancy Module (DBM).

All of our buoyancy clamping solutions are designed and manufactured in strict accordance with offshore industry standards, ensuring there is no slippage regardless of the operating environment. From standardised clamps, where the technical demands are more benign, to the highest performing clamps we have the right solution for you.

Our latest clamp developments have overcome the deep-water challenges related to large pipeline contractions combined with axial loads associated with what are understood to be the largest modules ever supplied.

Continue reading below to find out more...

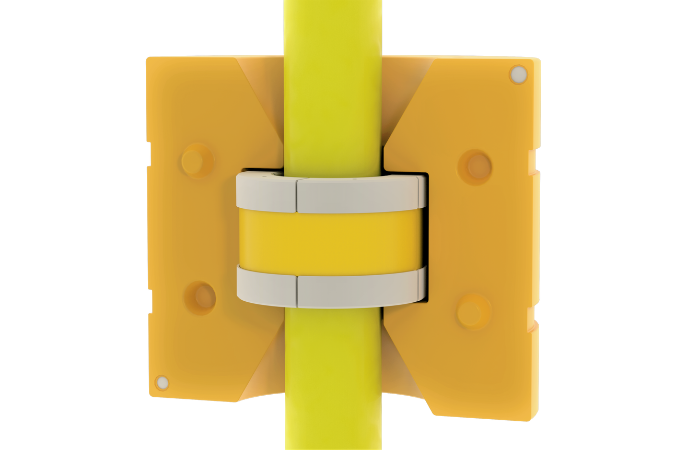

Uniform clamping pressure around the pipeline eliminates risk of damage

Ultra-high axial load capacity

Accommodation of large diametric contractions

Safe and quick installation

API 17L qualified

In accordance with offshore industry design standards

Steel catenary risers (SCRs)

Insulated and non-insulated flexible risers

Rigid pipes

Umbilicals

Flowlines

Jumpers

Cables

We were approached with a challenge to develop a clamp solution to overcome an insulated pipeline diameter contraction of over 30mm, with special consideration to generate a controlled uniform circumferential clamping pressure, to eliminate the risk of damage to the pipeline. Using our previously qualified materials we were able to deliver a solution that met industry requirements, thereby mitigating risks to qualification, scheduling, cost and quality.

For a recent steel pipe (SCR) project there was the desire to reduce installation time and logistics costs through supplying the largest modules possible. CRP Subsea supplied a qualified clamp technology which permitted axial loads in excess of 20 tonnes, whilst also meeting large diametric contractions due to pipeline insulation creep. The solution offered the optimum project costs opportunities, throughout delivery, transportation and installation. This technology can also be used on all other SCR’s, rigid pipes, flexible risers, jumpers and spools.