March 12, 2019

Feature article – Contributing to the future of wind power generation

We are witnessing the most exciting time for the renewables industry in real time. As the worldwide demand for renewable energy is growing, companies are independently supporting and driving the innovation of competitive clean power. With many countries across the globe setting goals for renewable energy supply targets and the completion of the first offshore wind project in the United States, the future of wind power generation is in the hands of visionaries.

Floating vs Fixed

So far, the rapid growth in the offshore wind market has been achieved using fixed platforms. Typically, turbines are secured using monopile or jacket structures attached to the seabed. Similar growth is anticipated in offshore floating structures where turbines are installed on a steel or concrete floating foundations that are moored to the ocean floor. Fixed or floating, these custom-built platforms are specifically designed to meet needs of the location where they will generate power for the lifetime of the windfarm.

The most significant difference between the two structures is the depth at which they can operate. For fixed platforms, their viability reduces with increasing water depth, whereas floating platforms can be placed in deeper waters. These floating structures provide the ability to tap into the rich and vast wind resources further offshore. Various countries across Europe and Asia, as well as the USA, are actively pursuing the development of floating wind technology in order to substantially increase their wind power generation capacity. Locating future windfarm projects further offshore can also help navigate the challenges of visual pollution and accommodation for fishing areas and shipping lanes.

For both fixed and floating wind, the uptake and development of technologies to drive the energy efficiencies, commercial viability and growth is rapid and exciting. CRP Subsea (formerly Trelleborg Offshore UK) has focused on applying its experience and expertise in providing solutions to overcome critical challenges and contribute to this continued growth. Particularly on power cable reliability for life of field.

Critical cable protection

Both fixed and floating platform arrangements, energy generated by the turbines is sent onshore through high voltage subsea electrical power cables. These cables are subjected to a variety of motions and loads during their installation and operational lifetime. Due to their location, cable failures or faults can be very costly and severely impact a windfarm’s performance and revenue.

Enhancing fatigue protection for fixed wind cables

For fixed windfarms, power cables are used to connect the fixed turbines together into an array, which transfer the energy generated back to the substation (electrical hub of the windfarm) and to the shore.

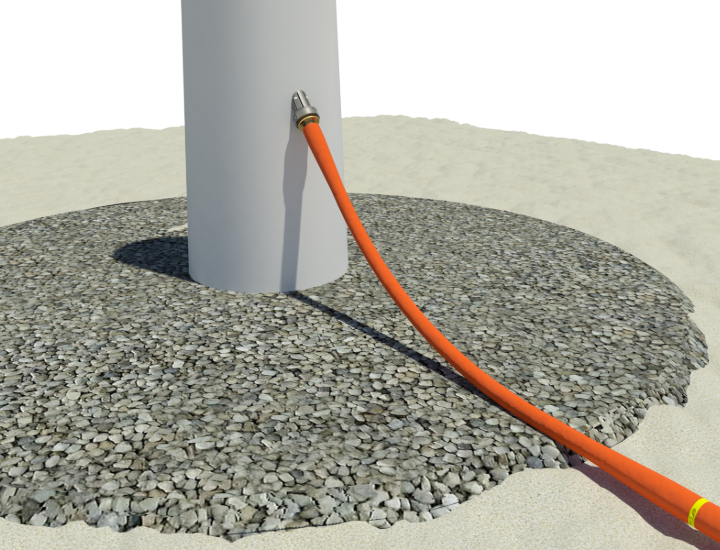

The entry and exit point for the power cables at each turbine and at the substation is of particular importance as they will see significant loads and motions resulting from a relentless combination of wave height, water depth, storm conditions and tidal currents throughout the life of the field. These areas can see significant cable fatigue and damage; therefore, protection is required from each entry and exit point to the burial point. In some cases, the burial point can be 20 to 30 meters from the turbine base with a significant free span. CRP Subsea’s (formerly Trelleborg Offshore UK) experience in dynamic cable protection overcomes these issues using tried and tested design methodology and materials.

One such solution is CRP Subsea’s NjordGuard. Both easy to assemble on the vessel and quick and reliable to install subsea, NjordGuard is a cable protection system specifically designed for protection of the cable at these entries and exit points.

As an integrated protection system designed for dynamic service, NjordGuard incorporates CRP Subsea’s proven dynamic bend protection methodologies to not only protect the cable from over-bending during installation and extreme storm conditions but crucially to also protect the cable from fatigue under sustained cyclic loading which is generally the main cause of fatigue. As with oil and gas and floating wind dynamic bend stiffener products, the Njordguard system incorporates homogeneous elastomeric cones with a geometry and material properties designed to provide a gradual and tailored transition in stiffness from its tip to its base for the cable as it approaches the fixed entry point. As well as protecting the cable from over-bending, this gradual, increase in stiffness is vital for fatigue protection as it provides continuous support under all load cases in all directions to the cable, distributing the loads and preventing any sudden stress transitions.

Protecting dynamic cable configurations on floating platforms

In floating wind production environments, power cables are used to connect the floating turbines back to the substation on the seabed (electrical hub of the windfarm) and the shore. The offshore environment is often dynamic and demanding and these power cables can be prone to mechanical and fatigue damage if subjected to excessive loads and motions. Securing, guiding and protecting these critical power cables is therefore of utmost importance. Incorporating cable protection, such as dynamic bend stiffeners, distributed buoyancy modules, bend restrictors, abrasion and impact protection systems into the design of the windfarm can help prevent early cable failure.

The protection of cables connecting between the floating turbine and the seabed requires significant consideration as they experience continuous loads and movement throughout their service life resulting from the dynamic motion of the floating structure and the general sea conditions.

When modeling and analysing the cables in this application, there are several established cable configuration options that can be considered to bring the motions and loads on the cable within manageable levels. In more benign conditions, a free catenary of the cable down from the floating turbine down to the seabed may be suitable. However, in increasingly dynamic conditions, a midwater suspension of the cable by means of controlled buoyancy may be necessary. These configurations include “Lazy Wave”, “Steep Wave”, “Lazy-S”, “Steep-S”, and “Pliant Wave” and have frequently been deployed in the operations offshore, their selection dependent on particular field conditions and layout.

Fundamentally, however, each configuration enables an increase in the cable length to improve the compliance of the cable relative to the dynamic movement of the floating structure, reducing loads and motions on the cable to within manageable levels. Means of providing this midwater suspension of the cable is by midwater arches or distributed buoyancy modules. The latter has become more commonplace as they can be quickly installed on the cable during the cable lay operation and they do not require mooring or anchoring to the seabed.

In each of the cable configurations, including free catenary, whilst bringing the motions and loads into manageable levels, it is always vital to consider suitable bend protection of the cable at the fixed points where the cable enters the floating structure and terminates on the seabed.

Bend limitation devices, like bend restrictors and bend stiffeners, are designed to protect power cables from excessive loads and bending during installation and service.

Both devices:

- Maintain the manufacturer’s recommended Minimum Bend Radius (MBR) during the life of the project

- Provide a suitable load path from flexible to fixed structures

- Reduce point loading at the termination to an acceptable level

However, their application point differs:

- For short term installation and long-term static loads on the cable, such as on the seabed termination point a bend restrictor would be applicable. Bend restrictors are a series of interlocking vertebrae molded from structural polymers and designed to lock together at a given radius, preventing the cable design bend radius from being exceeded.

- For dynamic applications where the cable is exposed to constant motion, such as on the entry of the cable into the floating turbine, then a bend stiffener is applicable. As previously mentioned with regard to NjordGuard, a bend stiffener comprises of a homogeneous elastomeric cone with a geometry and material properties designed to provide a gradual and tailored transition in stiffness from its tip to its base and this is crucial for the over-bend and fatigue protection of the cable. Many thousands of CRP Subsea’s dynamic bend stiffeners have been supplied to projects across the globe over 20 years with zero in service failures. The main drivers for this are the comprehensive design methodology, extensive material qualifications, and rigorous quality control processes during manufacture.

Radar interference mitigation materials

Wind turbines used for windfarms, regardless of whether they are fixed or floating platforms, can cause interference with radar missions related to air traffic control and weather forecasting on modern radar systems. The interference causes complications that include aircraft ghosting, sometimes called shadowing, false tracking plots, clutter, false storm warnings as well as hindering meteorological measurements.

In many instances, wind turbine sites are refused planning permission, which can often be in prime locations which cost millions of pounds in delays. In other cases, windfarm sites must scale back their plans and build fewer turbines (thus less power produced and smaller profits) due to the impact on radar systems. To maintain critical radar missions and accommodate future wind energy development opportunities, forward looking companies are working to develop new technologies to mitigate wind turbine radar interference.

Conclusion

As the worldwide demand for renewable energy continues to grow, the future of wind power generation continues to evolve. What we envision today for this industry will change drastically over the next couple of years as countries push for clean power generation and visionaries think up innovative ways to meet expectations.

Forward thinking companies like CRP Subsea are willing to step up to the challenge and are excited to take part in the future developments of this industry.

Andy Smith, Sale Team Manager, CRP Subsea

Daniel Bate, Sales Manager, CRP Subsea