March 11, 2021

Feature article – Creating safe buckling zones

Deepwater pipeline systems are designed to operate in harsh subsea environments, deep below the ocean’s surface, on the cold ocean floor that is made up of soil and sand, as well as teaming with marine life. In these turbulent waters, pipelines are exposed to changes in pressure and temperature. As the oil and gas industry moves further offshore into increasingly hostile and more remote places, modern field developers are requiring flowline designs that are longer with larger diameters, and which are lighter, running at higher temperatures.

Dynamic subsea environments

Operators traditionally spend a great deal of resources designing, manufacturing and installing pipeline systems to ensure they are fit for service. Great care is taken to verify their long-term integrity and that operational loads do not exceed extreme design parameters for the life of a project.

One challenge operators are taking into consideration in the design phase is the increasingly widespread build-up of axial forces along the pipeline due to temperature and pressure differences. This coupled with the influence of soil on the seabed, which can restrict free movement of the pipeline, causes a phenomenon called ‘lateral buckling’.

Damaging effects of buckling

Buckling typically occurs during start-up and shutdown sequences as thermal fluctuations cause pipelines to expand and contract, potentially resulting in downtime and unexpected costly shutdowns. Left unchecked, buckling can cause local axial strains severe enough for welds to fracture, the entire pipeline to collapse or even full bore rupture.

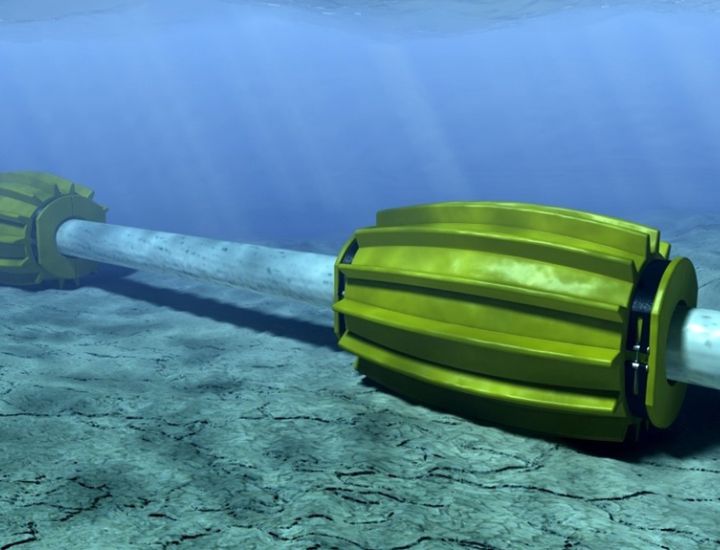

High-temperature subsea pipelines require special mitigations to prevent unpredictable lateral buckling fatigue cycles during operation and shut down events. Almost all deepwater subsea flowlines use mitigation devices to ensure safe lateral buckling, and one of the commonly used methods consists of attaching fixed buoyancy modules to sections of the pipeline.

In certain offshore conditions, lateral movement of traditional fixed buoyancy modules can cause soil compaction, increased lateral soil resistance and the formation of berms. Post-production subsea surveys and engineering evaluations show these berms may actually further restrict lateral movement, causing secondary regions of high stress. This further increases the risk of lateral pipeline buckling in other sections of the pipeline and affect fatigue life.

Predictable pipeline behaviour

Deepwater pipeline systems are often required to be held in specific geometric configurations subsea to prevent overutilisation of the system. Traditional non-rotating cylindrical buoyancy modules are installed to reduce weight and friction, while promoting controlled bending on pipelines. As outlined previously, in certain conditions, traditional fixed buoyancy modules displace seabed material creating ridges or berms of earth on the seafloor, which can start to restrict the lateral movement of the pipeline and the buoyancy modules, leading to buckling.

Rotating buoyancy technology solves this problem while increasing the robustness and safety of the system. It represents a step change in the way risks associated with buckling of high-temperature pipelines are managed and effectively mitigated. The advanced solution is engineered to reduce lateral friction and berm creation, thereby generating repeatable and predictable pipeline behaviour. In addition, the rotating buoyancy design reduces the number of modules needed along the pipeline, significantly lowering overall project costs for operators.

Testing information

The ability of advanced software analysis to produce high performance, robust and dependable solutions is revolutionising deepwater drilling and production. By increasing the performance of products before they even enter the water, software analysis is able to provide the solutions needed to combat the increasing harsh environments presented by the offshore world, virtually.

For rotating buoyancy technology, both small-scale and large-scale tests can be performed using prototype fixed and rotating buoyancy modules. By testing both options, CRP Subsea (formerly Trelleborg Offshore UK) can compare the two mitigation methods and validate performance with mathematical modeling techniques. The testing simulates each system’s in-service conditions, including pipeline weight, soil properties, soil interaction, and pipeline travel.

Conclusion

Doing business in today’s globalised markets requires a long-term approach with solutions that protect people, the environment and a customer’s investment. Forward-thinking companies are committed to improving the functionality of their products and solutions to provide wide-ranging benefits to meet and exceed customer needs.

As the search of new oil deposits goes further offshore and deeper in the ocean, new challenges will emerge and new solutions to meet them materialise. Uncertainty exists everywhere and with that, the unpredictable nature of lateral buckling is an unstable phenomenon that can be managed with innovative solutions like rotating buoyancy modules.

Steven Bray, Sales Team Manager, CRP Subsea

Find out more about Rotating Buoyancy Modules here